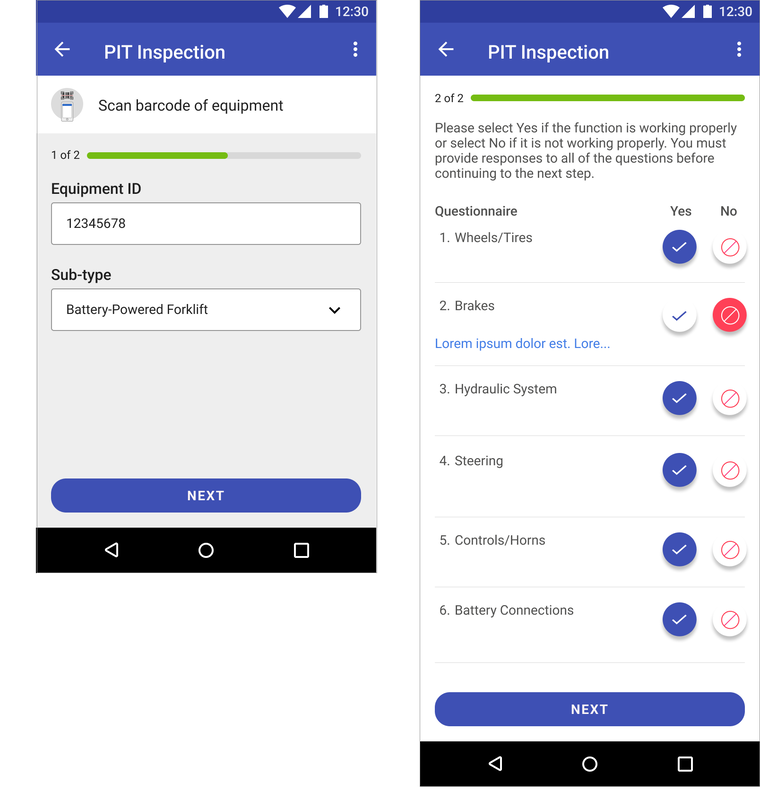

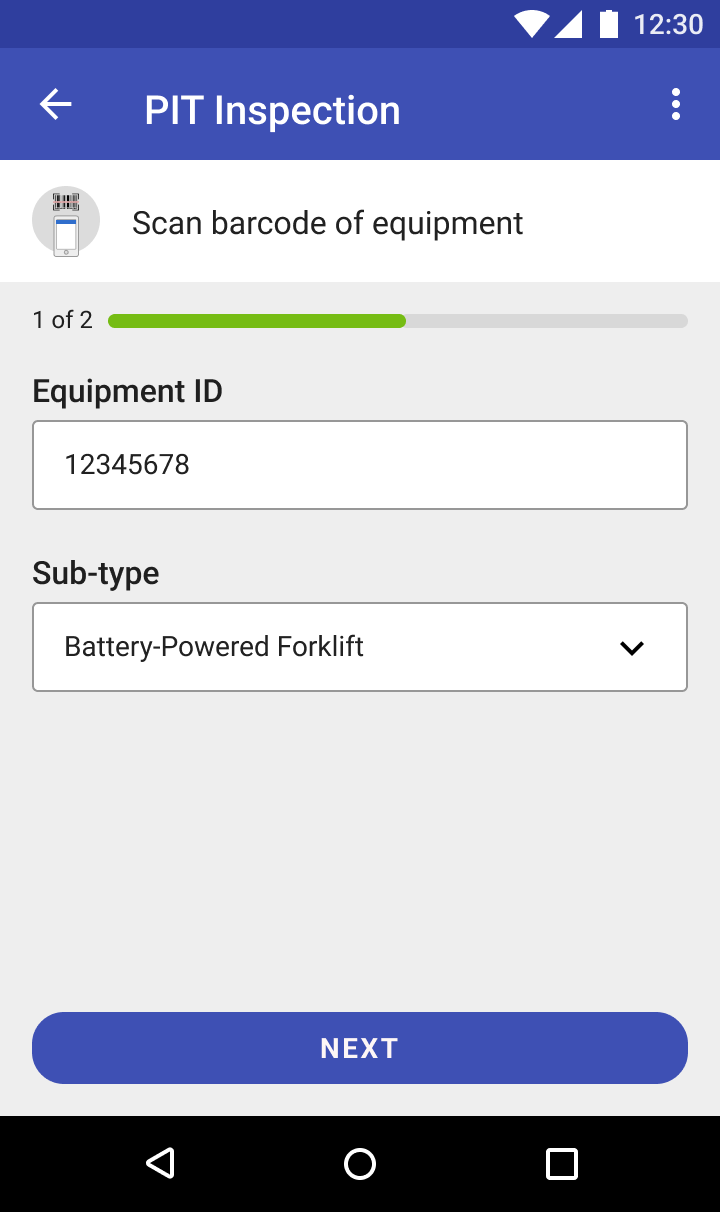

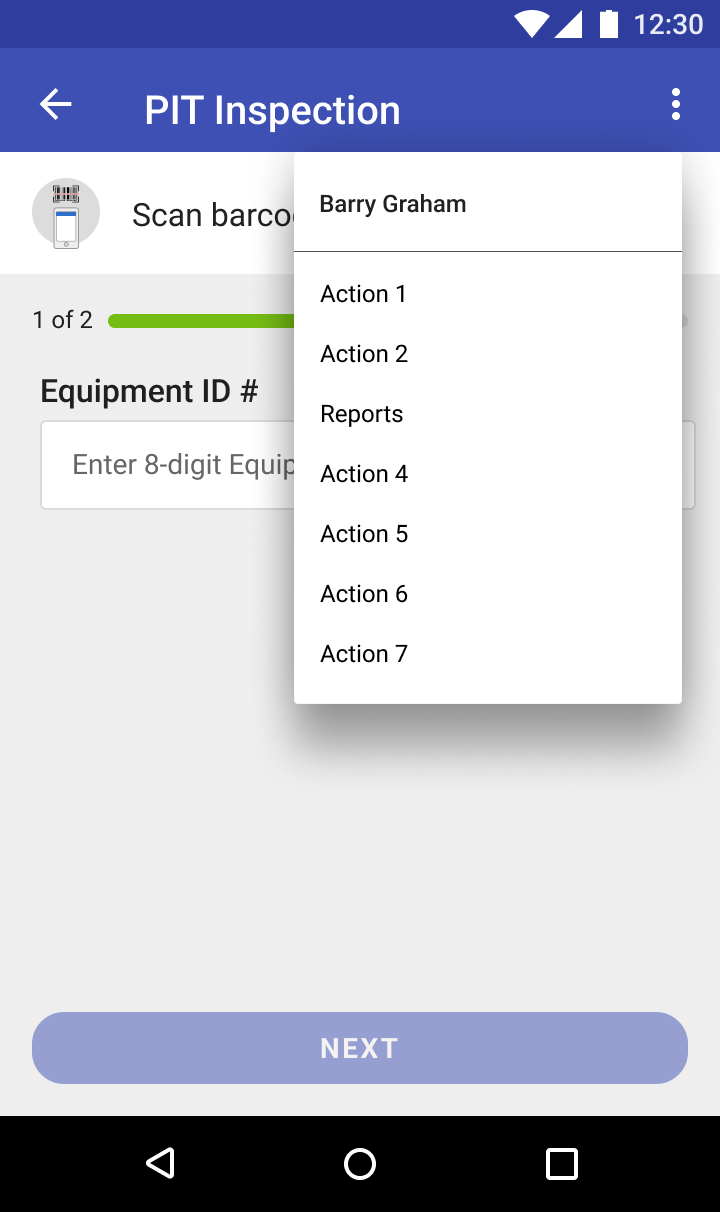

PIT Inspection

|

Platform: Mobile (Android) - Deloitte Studios

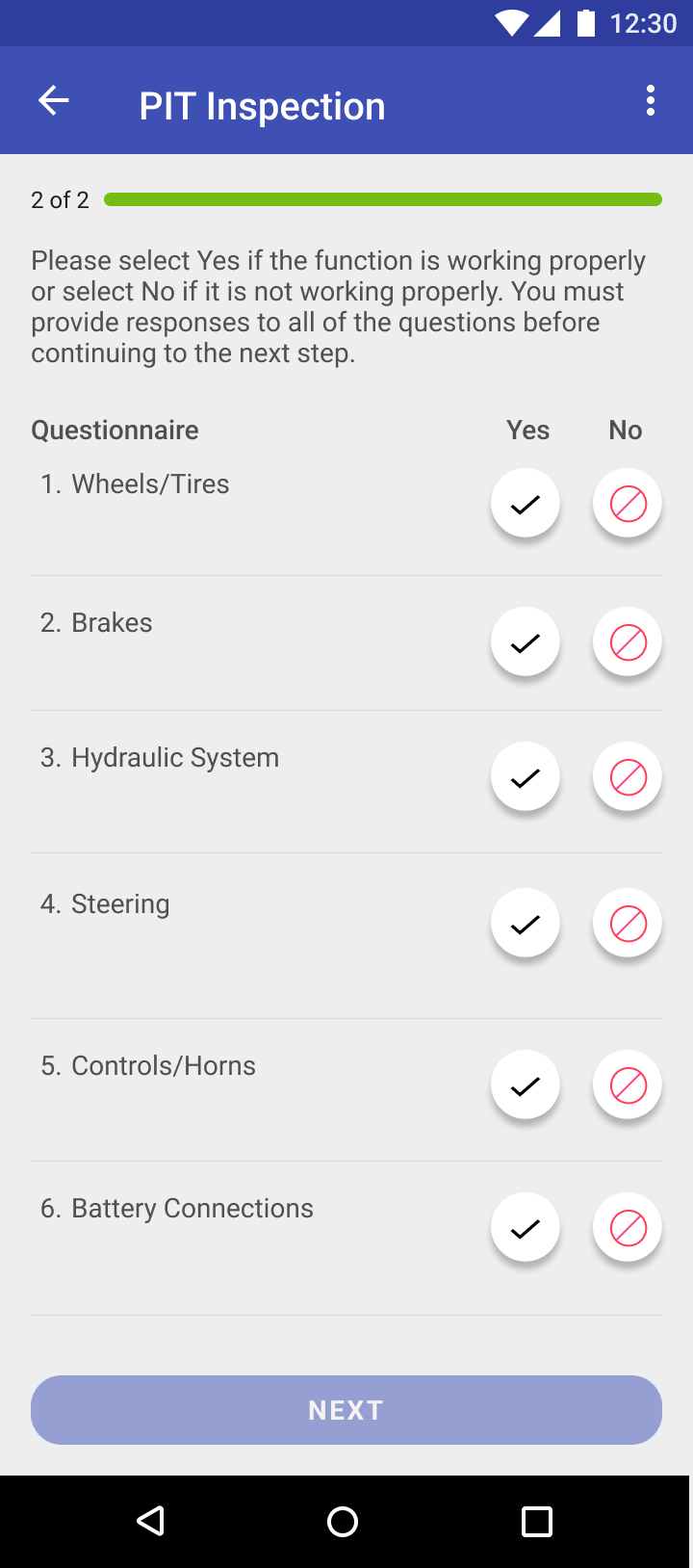

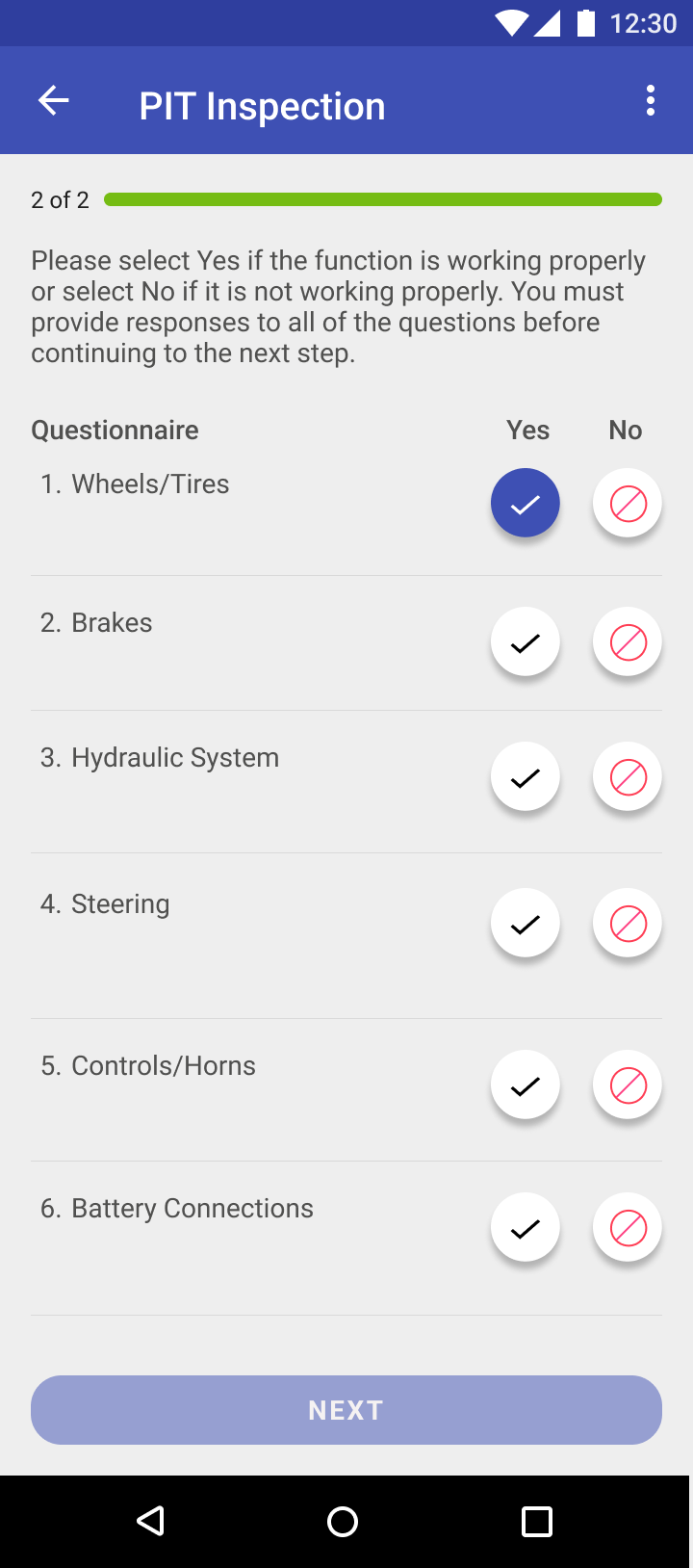

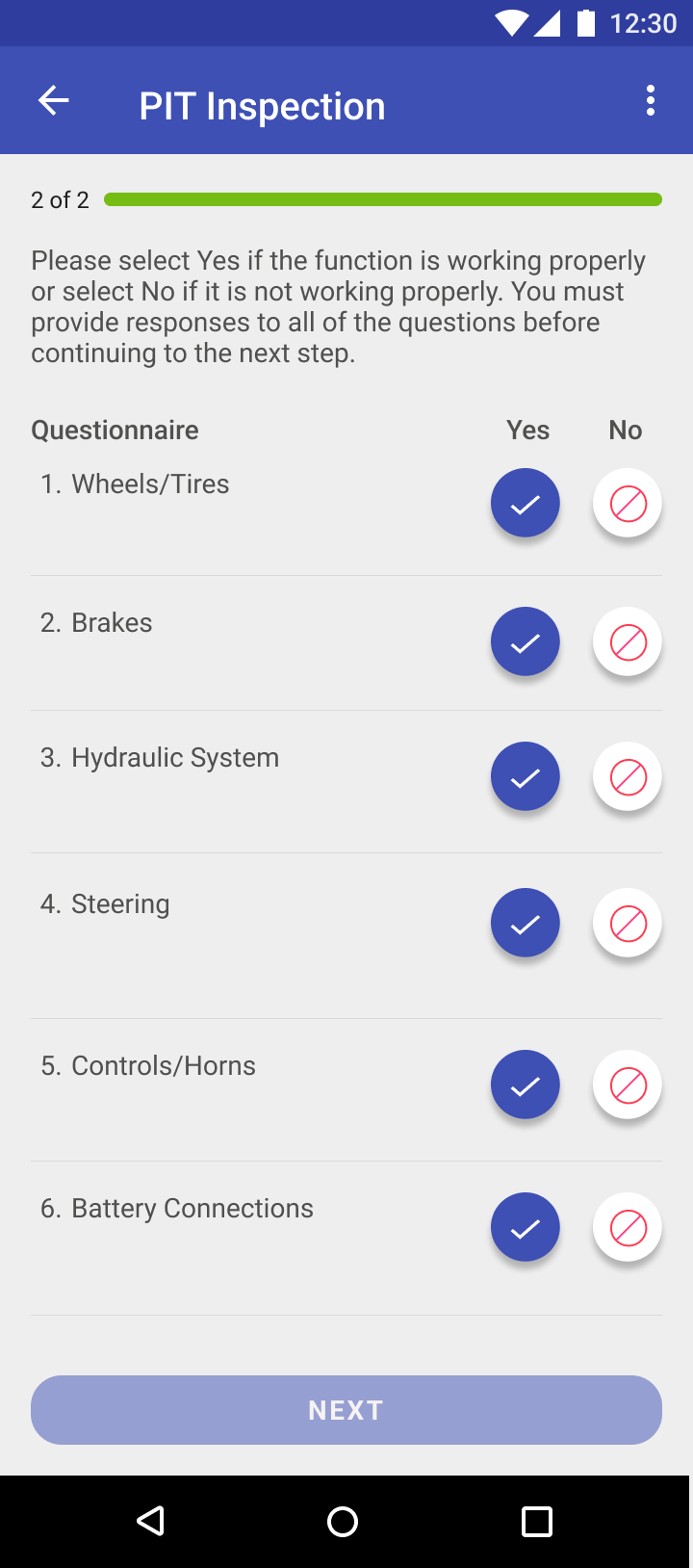

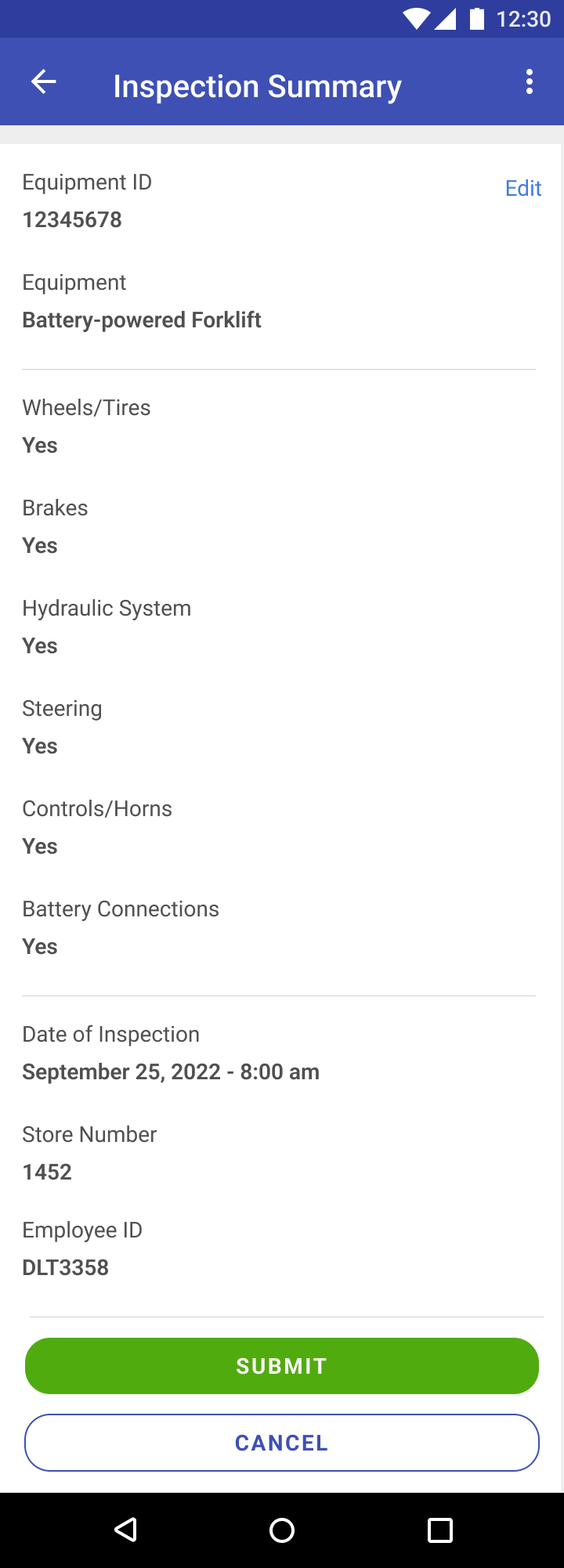

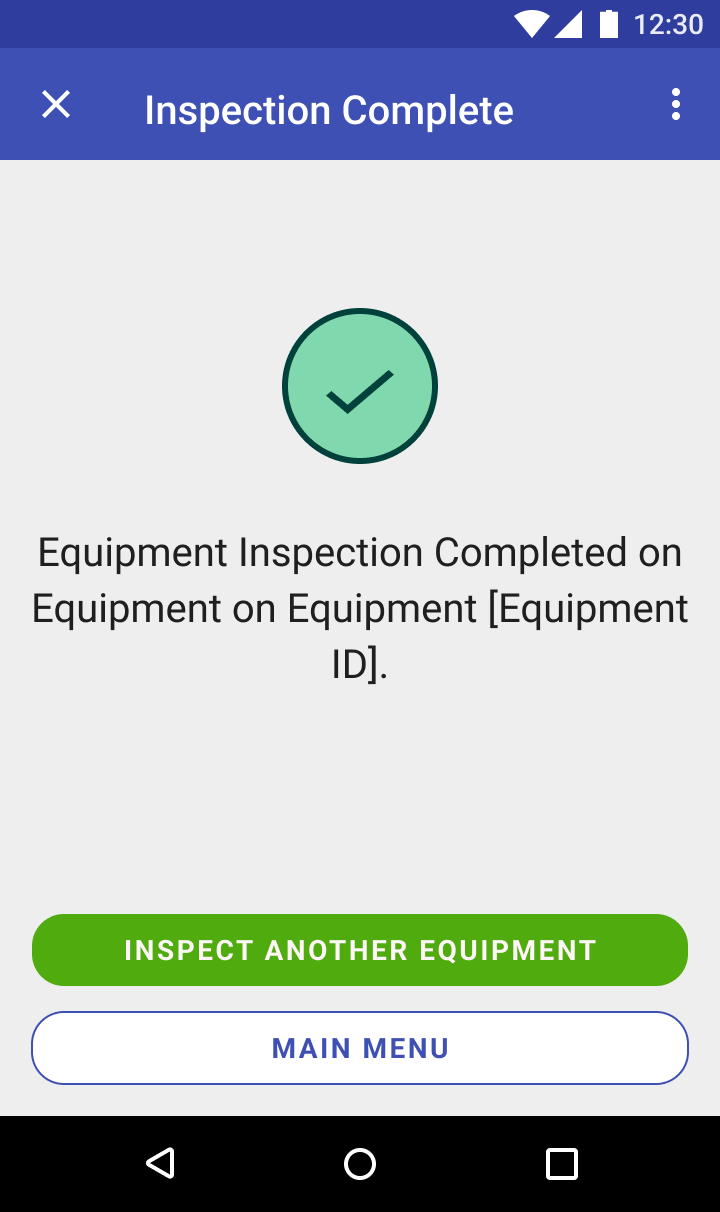

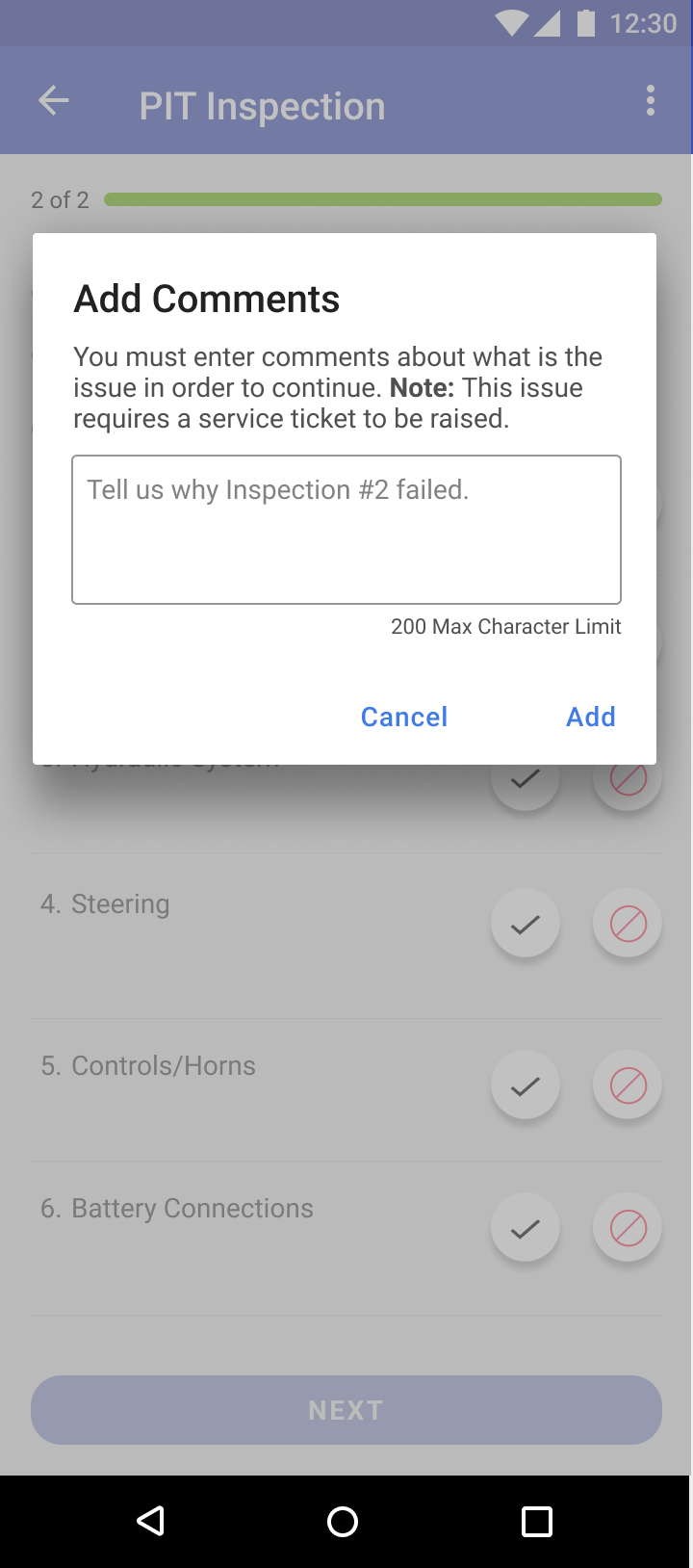

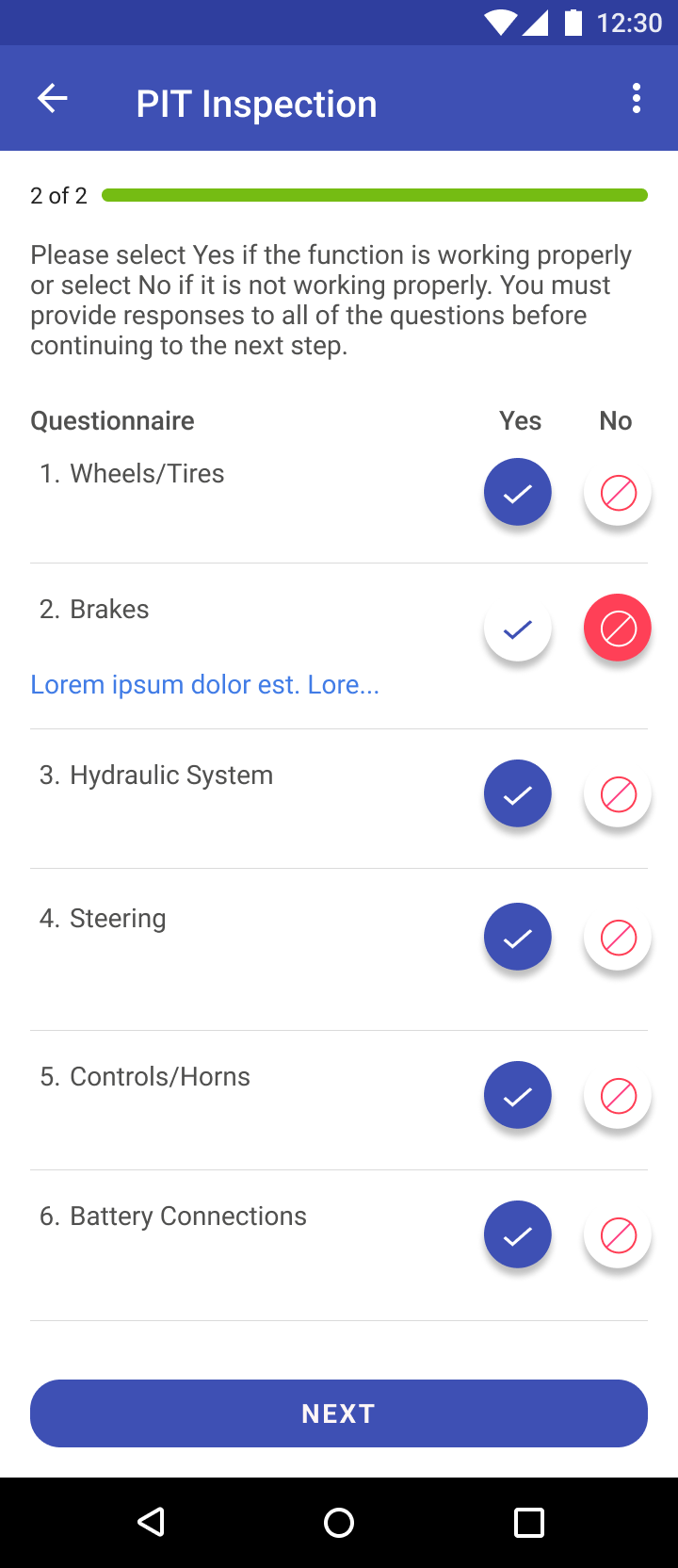

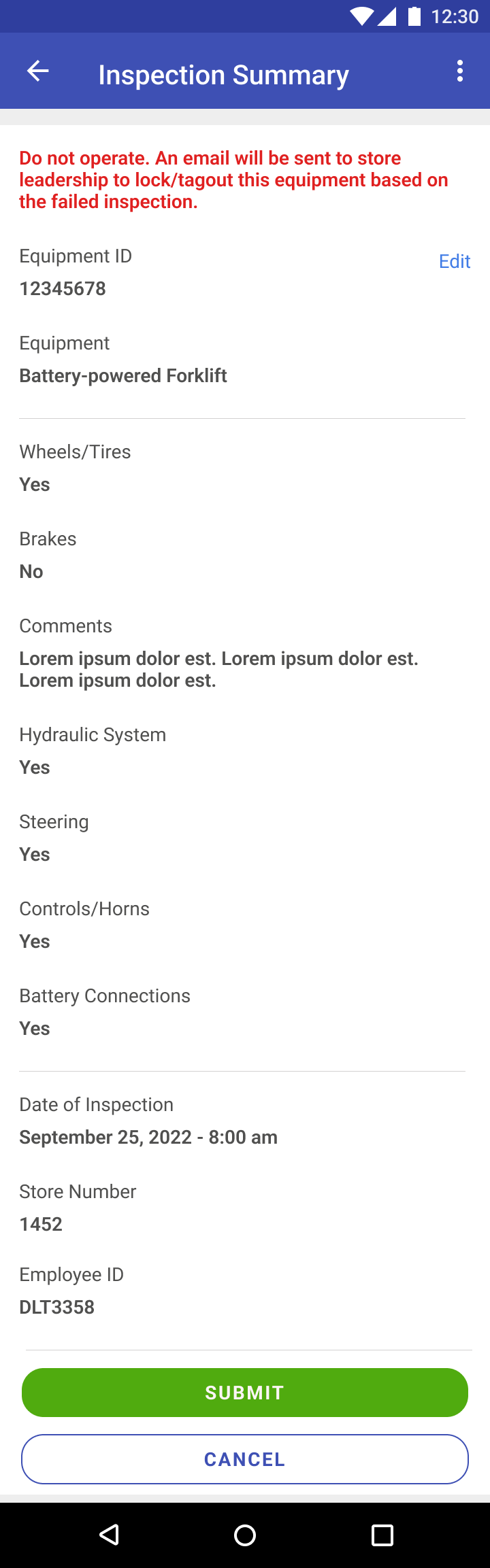

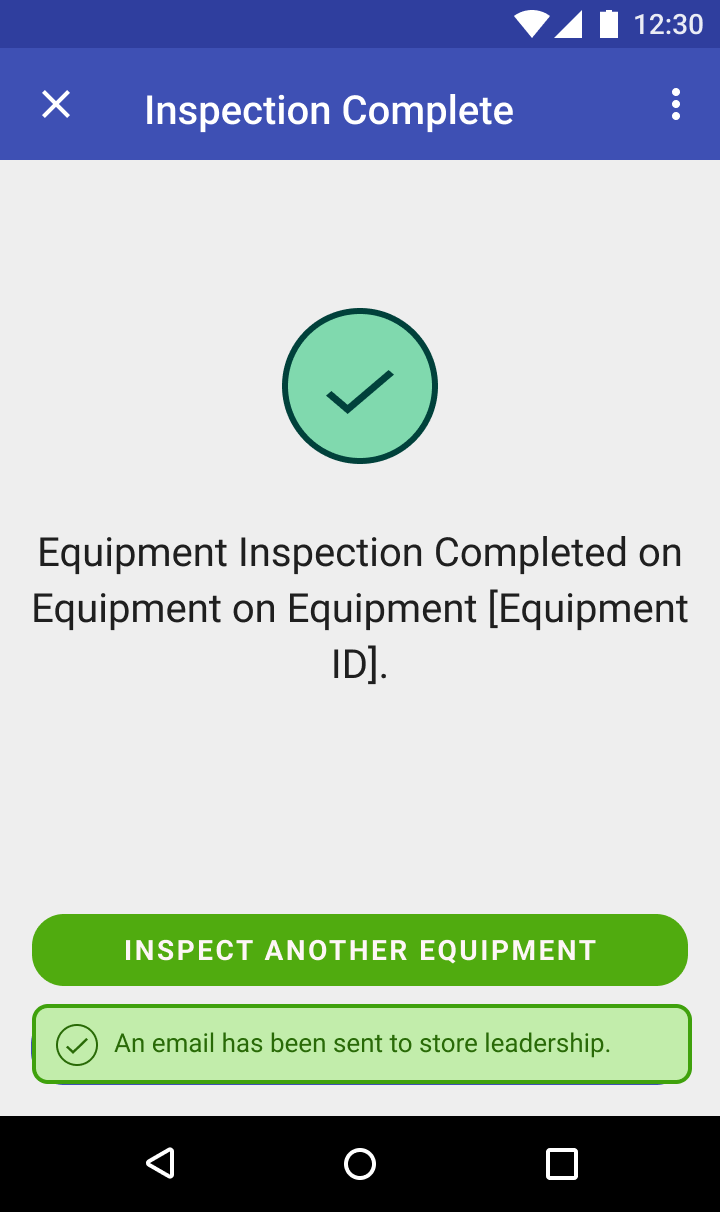

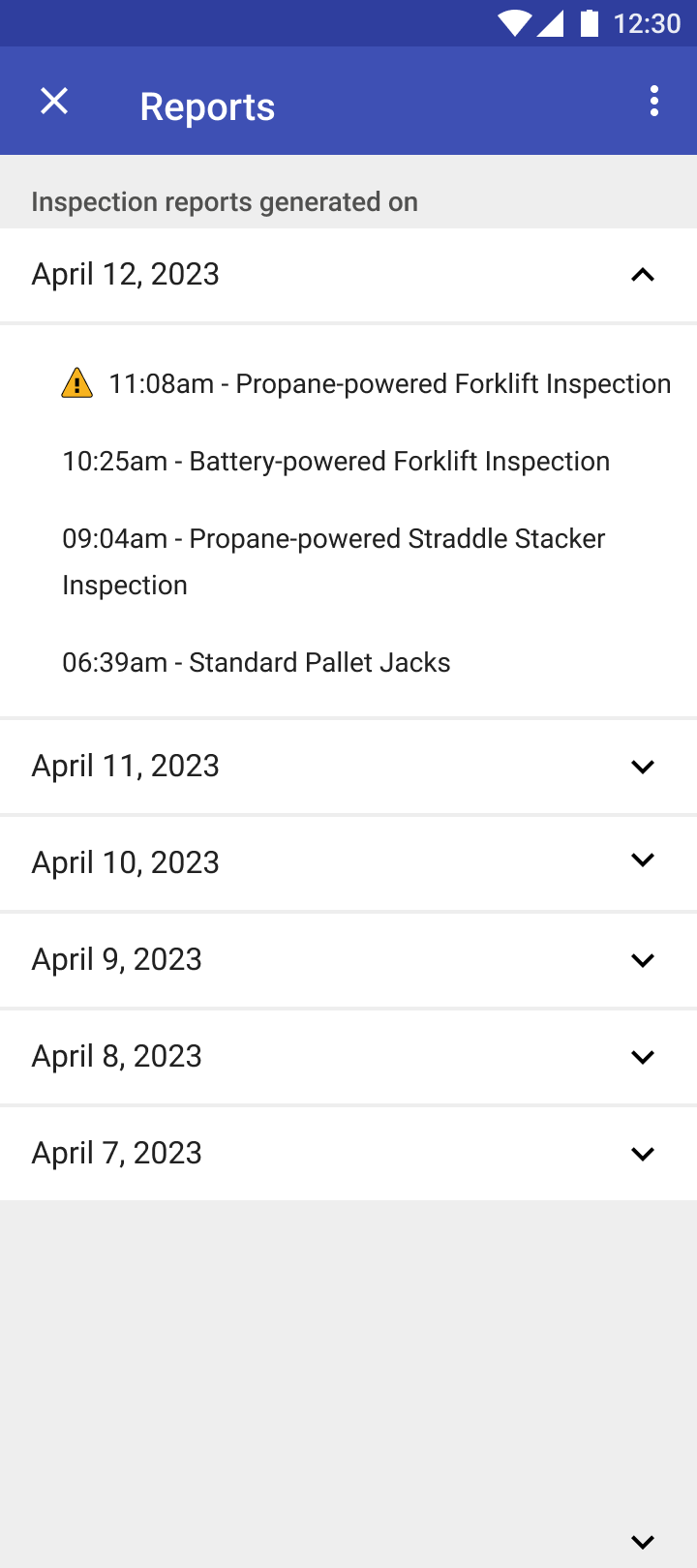

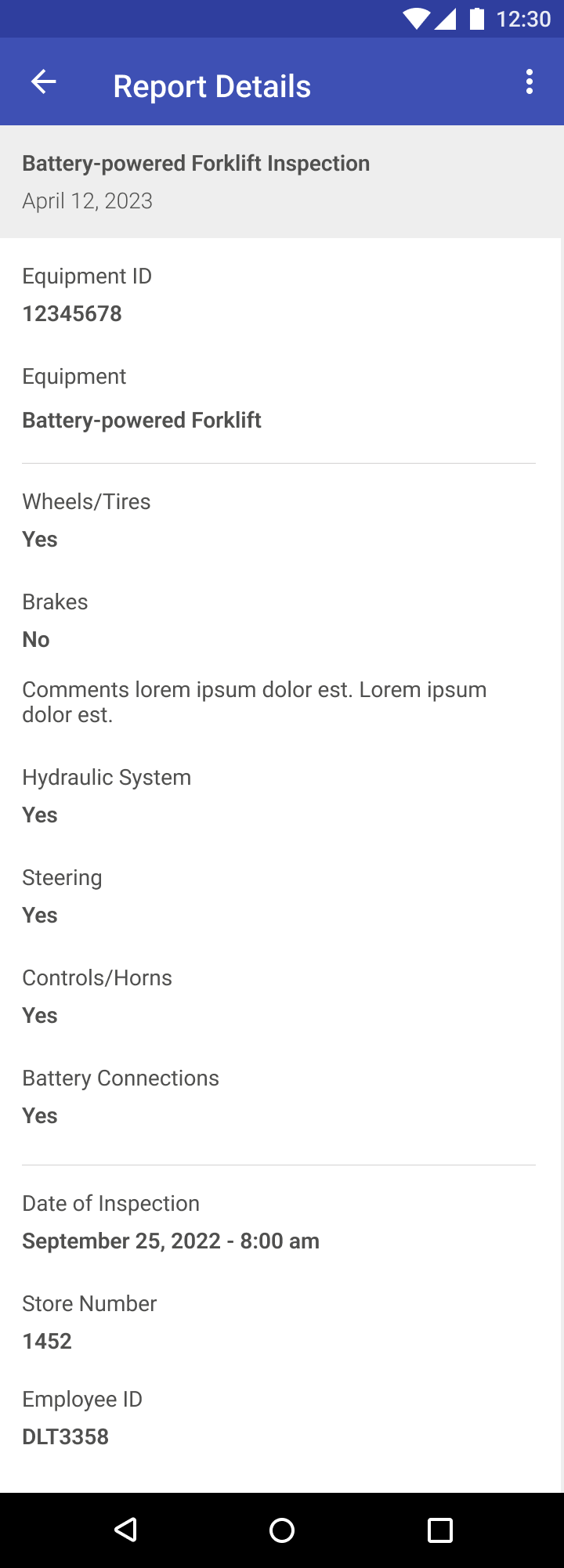

The PIT Inspection tool is part of the Kroger's Compliance suite of applications that allowed store associates to inspect Personal Industrial Trucks (PIT) by scanning each vehicle and recording their responses on the app to meet the store and OSHA safety guidelines. |

My Role

My role was a product designer responsible for discovery, user research, design, prototyping, and testing.

The Challenge

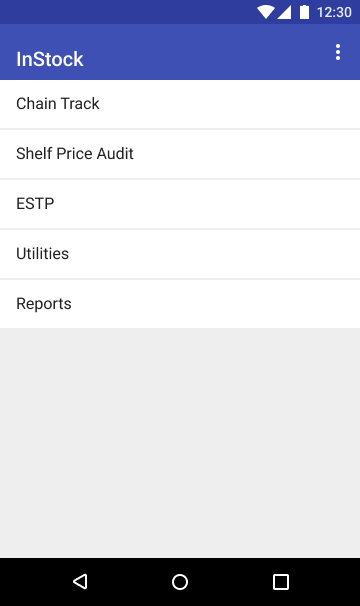

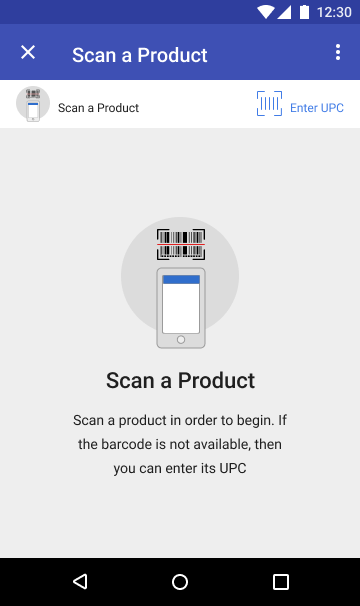

The challenge was how to get users to adopt a digital process on Android platform by incorporating multiple features; product scan, inspecting the vehicle by many inspection criteria, sending reports to store leadership for failed inspections and accessing 7 days of inspection repots , and all the while getting store associates to engage and adopt this application over previous versions.

Research: Personas and Associate Interviews

In order to better understand key insights from the business owners, I conducted multiple discovery sessions. I developed personas for associate and store manager who would be typical users of this application and use cases.